ZORN Pressure Filter ZPF 2.0

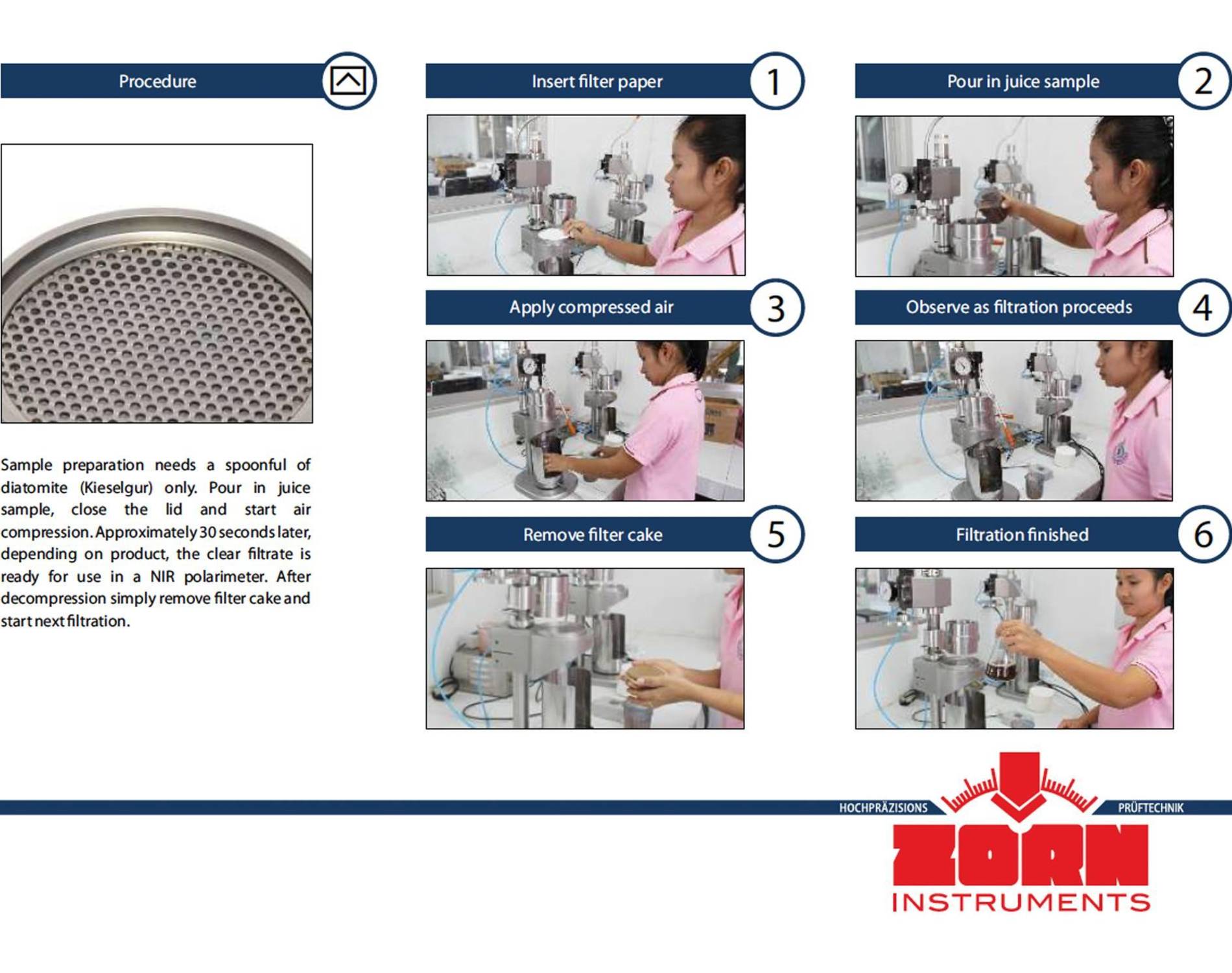

ZORN pressure filtration was developed for the clarification of difficult to filter liquids with the aid of compressed air. The replaceable filter element that can be sterilised and with a filtration area of 65 cm² is designed for round filters with a diameter of 110 mm. This solution was developed for, among others, the sugar industry and in this industry specifically for smaller, decentral cane sugar processing plants in tropical regions. By means of the use of the purely physically operating filter, it has been possible to replace the filtering of cane sugar juice with lead acetate common a few years ago. This is how protection of the environment really works.

Robust and maintenance-free

The device is robust and largely maintenance-free. Reliable operation is possible after short instruction, without the need for specialised knowledge. A central element of the filter unit is the replaceable filter element. This type of construction permits easy cleaning and short filtering times. The filter element is sealed by a strong cover with valve and pressure gauge. The pressure increase in the filter element can be regulated using an additional regulator valve. The catch is an easy to operate eccentric arrangement. The filter unit is made of stainless steel and is designed for an operating pressure of 6 bar. A removable polyethylene funnel guides the filtrate into the sample beaker. A low-noise compressor completes the system.

ZORN Pressure Filter ZPF 2.0

chemical-free cane juice filtration

We might do sweet as well – Pressure filters for sugarcane mills in Thailand at ZORN INSTRUMENTS we design and manufacture testing equipment for various application fields. This week we are sending a batch of ZORN ZPF 2.0 pressure filter devices to Thailand. They will be deployed at sugarcane mill laboratories. The filters clear samples of raw sugar juice from fibers and particles before they are...

Click here to go back to the products.