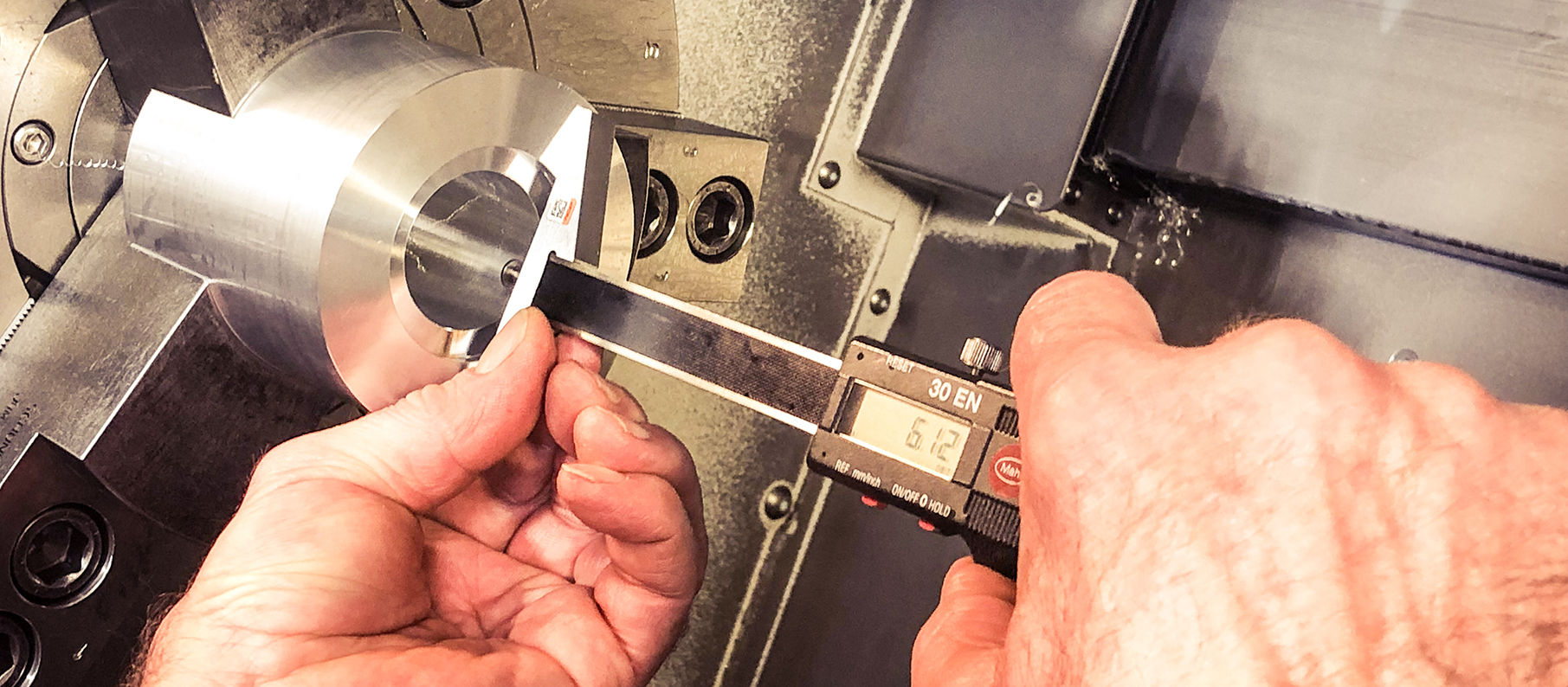

Milled CNC parts

We manufacture with high-precision CNC turning and milling machines both series components in small and large quantities as well as individual prototypes, special designs and spare parts. We work with different materials from aluminum to plastic and manufacture CNC workpieces of any complexity. The resulting custom-made products (individual production and small series) are used, among others, in the fields of medical and food technology, automotive, industrial fittings and special machine construction.

Quantity: prototypes, small, medium and large series on request.

Size: according to our machinery, which is constantly expanding!

Tolerance: The standard machining tolerance of most CNC machines corresponds to today's machining standard. Machining tolerances can be adjusted to customers' needs if necessary.

Design

Thanks to decades of experience and our own development department, we succeed time and again in perfecting existing devices and developing new workpieces. In this context, the close cooperation with universities and other scientific institutions, which has usually been established over many years, proves to be particularly useful time and again.

What is CNC turning?

CNC turning is a computer-aided manufacturing technology that produces components by rotating a solid workpiece while fixed cutting tools remove material from it, giving it its final shape. All processes run automatically according to the machining programs uploaded to the CNC lathe.

What is CNC milling?

CNC milling is a computer-aided manufacturing technology. Here, a milling cutter is used to remove material from a solid workpiece. The types commonly found in the industry are for example:

- 3-axis CNC milling machines (X,Y,Z alignment)

- 5-axis CNC milling machines (X,Y,Z + A- rotation around the -axis, B - rotation around the Y-axis).